The quality of your products is more than just a reflection of your brand—it’s a key determinant of your profitability and long-term sustainability. Whether you’re operating on massive platforms like Amazon or running your independent online store, the quality of the products you deliver directly influences your brand’s reputation, customer trust, and, ultimately, your bottom line.

Introduction

In the world of e-commerce, particularly on platforms like Amazon. Every decision can elevate your brand to new heights or cause it to spiral downward, potentially beyond recovery. The online marketplace is fiercely competitive, and customers have countless options. Your brand’s reputation is everything in this environment, and it can be built or destroyed with just a few clicks.

One of the most crucial yet often overlooked aspects of running a successful online business is the importance of product inspection. While many sellers focus on aesthetics, marketing strategies, and customer acquisition, they often neglect the backbone of their operations—ensuring that the products they deliver are of the highest quality. Product inspection is not just about checking a box or meeting a regulatory requirement; it’s about safeguarding the integrity of your brand and ensuring that every product that leaves your warehouse meets your customers’ expectations.

How Cutting Corners Can Affect Your Brand’s Reputation

Running a business is a lot like playing a complex video game. Each decision, from choosing the right products to implementing a robust product inspection process, is akin to leveling up in a game. Just as in gaming, where shortcuts often lead to missed opportunities or even game-over, cutting corners in business—especially in quality control—can devastate your brand’s reputation.

Imagine the scenario: You’ve invested time, money, and energy into creating a product, developing a marketing strategy, and building a customer base. However, you decide to forgo thorough product inspection to save costs or expedite production. Initially, everything might seem acceptable. However, as defective products start reaching your customers, the negative reviews begin to pile up. Once associated with quality, your brand starts to be seen as unreliable.

This is not just a hypothetical situation; it’s a reality many sellers face. The allure of saving money by skipping product inspection often leads to a much higher cost in the form of lost customers, poor reviews, and even suppressed listings on platforms like Amazon. The damage to your brand’s reputation can be irreversible, making it clear that cutting corners is never worth the risk.

What is a Product Inspection?

At its core, a product inspection evaluates goods to ensure they meet specific quality standards before they are delivered to the customer. This process involves checking the products for compliance with both your specifications and any relevant federal or governmental requirements.

Product inspections are typically conducted at the manufacturing site, where inspectors assess the products based on various criteria such as functionality, durability, appearance, and overall quality. The goal is identifying defects or inconsistencies affecting the product’s performance or customer satisfaction.

There are different types of product inspections, each serving a unique purpose. Some of the most common include pre-production, during-production, and pre-shipment inspections. These inspections help to identify and address any potential issues before the products reach the end consumer.

Why Regular Inspections Are Critical for Maintaining Quality

Consistent product inspection is not just a one-time event; it’s an ongoing process that plays a critical role in maintaining the quality of your products. Regular inspections allow you to catch any issues early, ensuring they do not escalate into more significant problems.

When you implement a regular product inspection schedule, you are actively working to maintain the standards your customers expect. This proactive approach helps to minimize the risk of defects, reduce the number of returns, and maintain customer satisfaction. It also signals to your customers that you are committed to providing high-quality products, which can enhance your brand’s reputation and customer loyalty.

In the competitive world of e-commerce, where customer reviews and ratings play a significant role in a product’s success, maintaining consistent quality through regular product inspections is not just advisable—it’s essential.

How Do I Determine the Right Sample Size for My Inspections?

Determining the right sample size for your product inspections is a critical decision that can impact the effectiveness of your quality control efforts. The sample size you choose will determine how accurately you can assess the overall quality of your product batch.

To understand this better, consider the analogy of assembling a team for a video game. You can’t possibly vet every player in the game, but carefully selecting a sample size of players increases your chances of building a winning team. Similarly, in product inspections, the larger your sample size, the more accurate your quality assessment will be.

The level of risk often determines the sample size for a product inspection you are willing to accept. A larger sample size means a lower risk of defects slipping through the cracks, while a smaller sample size might save you money but increase the chances of faulty products reaching your customers.

In practice, determining the right sample size involves balancing cost and risk. For example, if your product is high-value or has a critical safety component, a larger sample size might be necessary to ensure that every unit meets the required standards. On the other hand, a smaller sample size might be sufficient for products with a lower risk of defects.

Sample Size Levels and Defect Discoverability Percentage

When selecting a sample size for product inspections, it’s essential to understand the different levels of inspection and their implications. The level of inspection you choose will determine the percentage of defects that can be discovered within your sample.

- Level I: This is the most basic level of inspection, with a small sample size. It is generally only recommended if you have a shallow risk of defects or have a long-standing, reliable relationship with your manufacturer. The smaller sample size at this level means there is a higher chance of defects going unnoticed.

- Level II: This level is the most commonly used and balances cost and thoroughness. It is suitable for most products and is particularly useful for brick-and-mortar stores, where defective products can be easily returned or exchanged without significantly harming the brand’s reputation.

- Level III: This level involves the most rigorous inspection process, with a larger sample size and lower defect tolerance. It is recommended for e-commerce businesses, especially those selling on Amazon, where negative reviews can significantly impact sales and brand reputation.

The defect discoverability percentage (DDP) is a critical factor to consider in product inspections. This percentage represents the likelihood of discovering a defect within your chosen sample size. For example, if you inspect 50 units out of a batch of 1,000, and your DDP is 2%, defects in the remaining 950 units could go unnoticed.

The larger your sample size, the higher your DDP, meaning you will likely catch defects before they reach your customers. This is why it is crucial to carefully consider your sample size and inspection level based on your product’s risk profile and your business’s tolerance for defects.

How Do Improper Inspections Affect My Amazon Store?

Improper product inspections can have far-reaching consequences for your Amazon store, impacting everything from customer satisfaction to your product’s visibility on the platform. When inspections are not conducted properly, defective products are more likely to reach your customers, leading to many issues that can significantly harm your business.

Thorough Inspections Can Save You Money and Protect from Bad Reviews

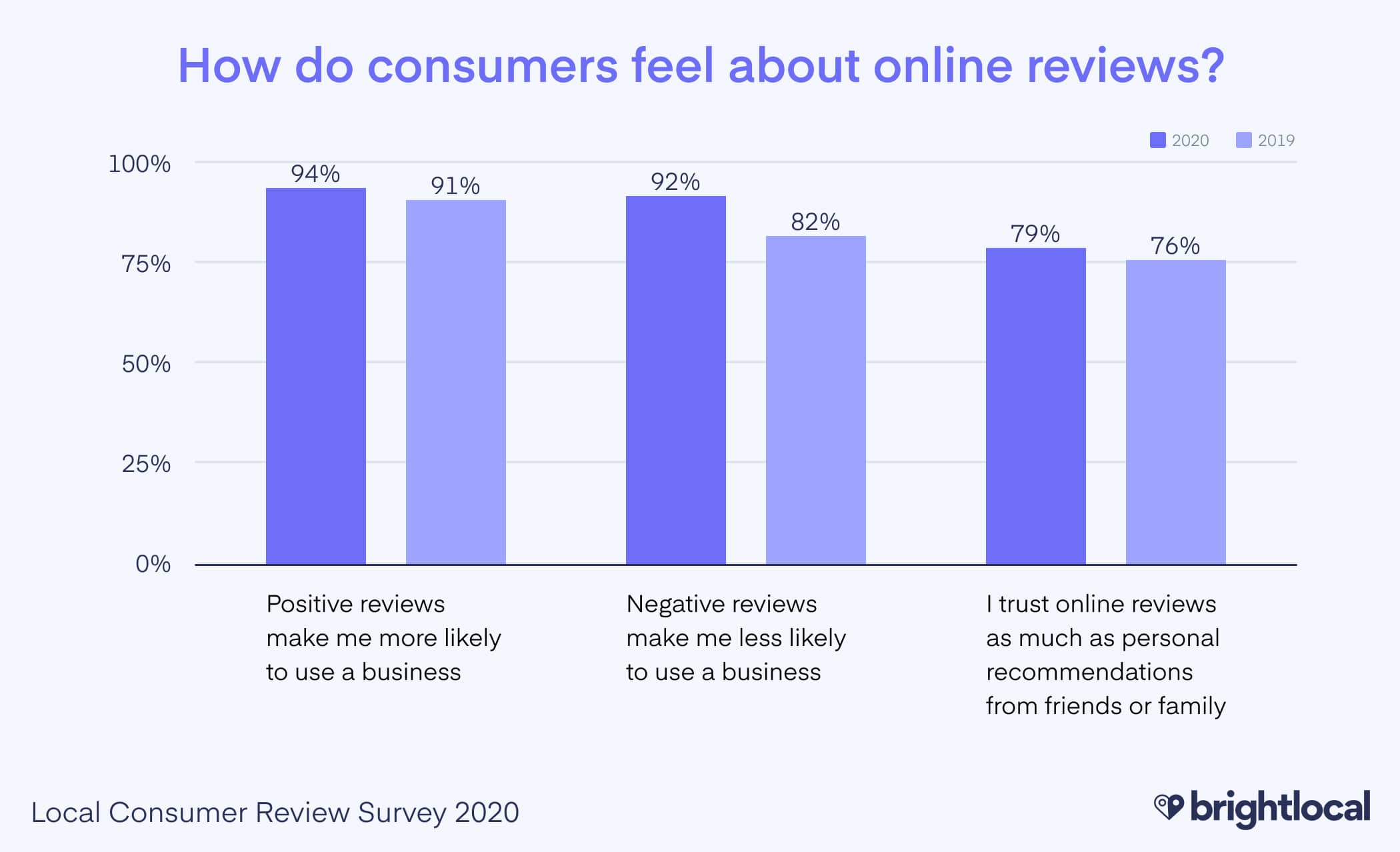

One of the most immediate effects of improper product inspections is the potential for negative reviews. Studies show that 91% of 18–34-year-olds trust online reviews as much as personal recommendations, and 93% of consumers say online reviews often influence their purchase decisions. In the world of e-commerce, where reviews are a primary factor in a product’s success, the impact of negative feedback cannot be overstated.

A thorough product inspection process can help prevent the distribution of defective products, reduce the likelihood of negative reviews, and protect your brand’s reputation. The cost of implementing a robust inspection process is often far less than the potential losses associated with poor reviews, returns, and subsequent damage to your brand.

Too Many Returns Can Suppress Your Amazon Listing

In addition to negative reviews, improper product inspections can lead to a high return rate, another major red flag for Amazon. The platform closely monitors return rates, and if your return rate exceeds its acceptable threshold, your product listing could be suppressed. This means your product will no longer appear in search results, severely impacting your sales and visibility on the platform.

Amazon’s primary concern is customer satisfaction, and they have stringent policies to ensure that sellers maintain high standards. Suppose your products consistently fail to meet these standards due to poor product inspections. In that case, you risk losing sales and damaging your relationship with Amazon, which could lead to further penalties.

How Does Amazon Calculate Your Order Defect Rate?

The Order Defect Rate (ODR) is a critical metric that Amazon uses to assess the quality of your products and the overall customer experience you provide. The ODR is calculated as the percentage of orders that receive negative feedback, A-to-Z Guarantee claims, or credit card chargebacks within 60 days.

A high ODR indicates that many customers are dissatisfied with your products, which is often a direct result of inadequate product inspections. If your ODR exceeds Amazon’s acceptable threshold, your account may be flagged, and your product listings could be suppressed or removed altogether.

To avoid this, implementing a rigorous product inspection process is essential to minimize the risk of defects and ensure that your products meet the highest quality standards. This helps keep your ODR low, enhances customer satisfaction, and protects your brand’s reputation.

Case Studies: Real-World Examples of Inspection Successes and Failures

To truly understand the impact of product inspections on your business, it’s helpful to look at real-world examples of successes and failures. In one case, a well-known electronics brand implemented a thorough product inspection process that included multiple levels of testing and a large sample size. As a result, they identified and addressed potential defects before their products reached the market, leading to high customer satisfaction and a strong reputation for quality.

On the other hand, a small e-commerce business decided to cut costs by reducing the scope of its product inspections. They opted for a Level I inspection with a minimal sample size, thinking it would be sufficient. Unfortunately, many defective units made it to customers, leading to negative reviews and returns. The company’s ODR spiked, and its product listings were eventually suppressed by Amazon, leading to a drastic drop in sales.

These examples highlight the importance of investing in a robust product inspection process. The cost savings from cutting corners are often outweighed by the long-term damage to your brand’s reputation and bottom line.

Defective Products Influence the Valuation of Your Company

When it comes to selling your business or attracting investors, the quality of your products plays a significant role in determining your company’s valuation. Defective products can have a direct impact on your financial performance, customer satisfaction, and overall brand reputation—all of which are critical factors in a company’s valuation.

Buyers and investors will closely examine your product return rates, customer reviews, and ODR as part of their due diligence. If they find that your products have a history of defects due to inadequate product inspections, they may lower their valuation or decide not to invest at all.

To maximize your company’s valuation, it’s essential to demonstrate that you have a rigorous product inspection process that ensures consistent quality and minimizes the risk of defects. This enhances your brand’s reputation and makes your business more attractive to potential buyers and investors.

Best Practices for Implementing an Effective Inspection Process

To implement an effective product inspection process, follow these best practices:

- Understand the Inspection Process: Make sure you thoroughly understand the product inspection process, including the different types of inspections and the criteria used to evaluate your products. This will help you choose the right inspection level and sample size for your business.

- Choose the Right Inspection Level: Select an inspection level that aligns with your product’s risk profile, budget, and customer expectations. For high-risk products, opt for a Level III inspection to identify and address any potential defects before the products reach your customers.

- Involve Your Inspector: Work closely with your inspector to ensure that they conduct the inspections thoroughly and provide you with detailed reports on the findings. Regular communication with your inspector is crucial for maintaining control over the quality of your products.

- Monitor and Adjust: Continuously monitor the results of your product inspections and be prepared to adjust your process as needed. If you notice an increase in defects or returns, consider increasing the frequency or scope of your inspections.

- Stay Informed: Keep up-to-date with industry standards and regulations related to product inspections. This will help you ensure that your products comply with all relevant requirements and maintain high quality.

Bottom Line

The importance of product inspection cannot be overstated. It is a critical business component that directly impacts customer satisfaction, brand reputation, and financial performance. By implementing a robust product inspection process, you can minimize the risk of defects, reduce returns, and enhance the overall quality of your products.

In the competitive world of e-commerce, where customer reviews and ratings can make or break a product, investing in product inspection is not just a smart business move—it’s essential for long-term success. Don’t let short-term cost savings lead to long-term losses. Instead, focus on providing high-quality products that meet or exceed customer expectations, and your business will thrive.

For businesses looking to optimize their Amazon operations, including implementing effective product inspection strategies, partnering with experts can make all the difference. Profit Whales offers comprehensive solutions designed to help you scale your brand and achieve sustainable growth in the e-commerce space. To learn more about how Profit Whales can assist you in driving success, visit Profit Whales.

If you’re ready to take the next step and improve your business processes,don’t hesitate to get in touch with us. Our team is here to provide the guidance and support you need. Reach out to us today through our Contact Us page.

FAQ

What are the common challenges in conducting product inspections?

Common challenges include:

- Selecting the right inspection level.

- Ensuring consistent quality across different batches.

- Managing the cost and time associated with thorough inspections.

How often should product inspections be conducted?

The frequency of product inspections depends on the nature of the product, the risk of defects, and customer expectations. High-risk products or those with critical safety components may require more frequent inspections.

What are the costs associated with product inspections?

The costs of product inspections can vary depending on the level of inspection, sample size, and the complexity of the product. However, these costs are often outweighed by the potential savings from reduced defects and returns.

How can product inspections improve customer satisfaction?

Product inspections help ensure that only high-quality products reach your customers, reducing the likelihood of defects and returns. This leads to higher customer satisfaction, better reviews, and increased brand loyalty.